Building a future where every journey is powered by the sun

What is Aptera?

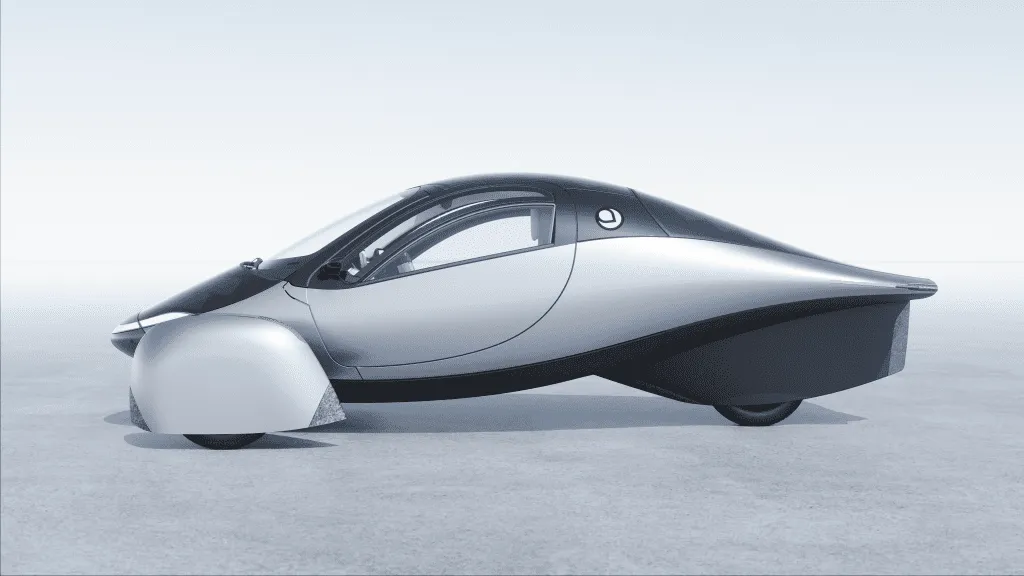

Aptera is a unique vehicle that is being designed with efficiency in all things as its guiding principle.

It is a 3-wheeled all-electric vehicle. Although it is classified as a motorcycle (technically, an autocycle),

it is the size of a compact car with seating for 2, butterfly doors, solar panels, and a range of up to 400 miles.

The design is so aerodynamic that it requires less than half the energy of other EVs. In fact, it is estimated that the wind resistance of the

entire vehicle is about the same as the side mirror on a Ford F-150 pickup truck. This leads to savings in many areas -

faster and easier charging, lower production and fuel costs, and extended range. It also lends itself to a lower overall cost.

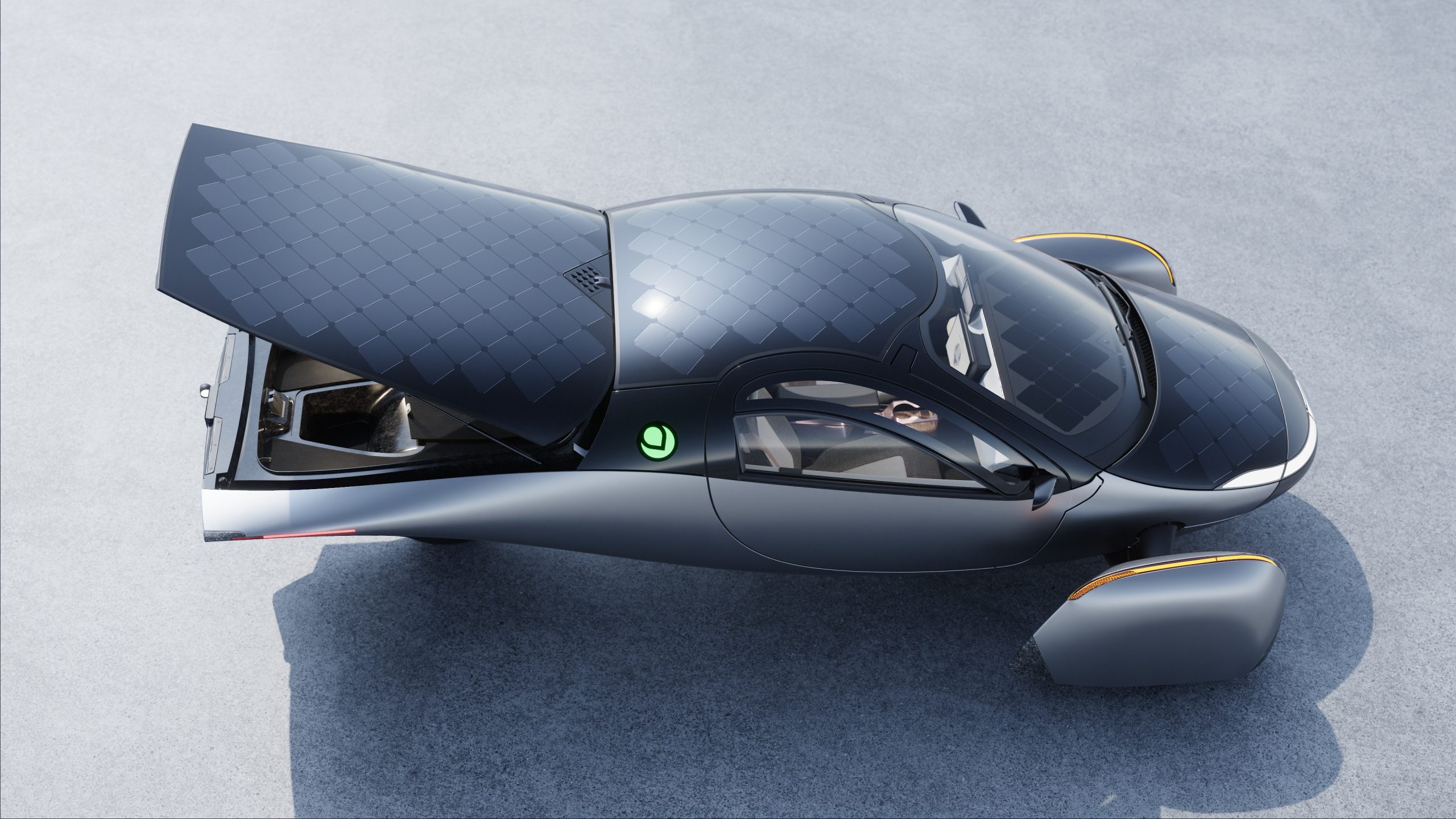

It has solar panels on the hood, dashboard, roof, and rear hatch to harvest solar power - driving or parked - and reduce charging needs.

It can easily charge at home using a standard 110v or 220v wall socket, or add up to 100 miles of charge at a standard Tesla DC Fast Charge station in only 10 minutes.

On a sunny day in areas it can obtain enough energy just from the sun to travel up to 40 miles.

The innovative manufacturing materials and methods are also focused on efficiency which has the added benefit of lowering the vehicle cost as well.

Specifications

- Length: 172 inches

- Width: 88 inches

- Height: 57 inches

| Hope Sheet | Spec Sheet | |

|---|---|---|

| Drag Coefficient | 0.13 | |

| Energy Usage | 100 Watts/Mile | |

| Range | 400 Miles | |

| Solar Charging | 40 Miles/Day | |

| Weight | 1,800 lbs | |

| 110v Charge Speed | 13 Miles/Hour | |

| 240v Charge Speed | 57 Miles/Hour | |

| Tesla Rapid DC Charge Speed | 500 Miles/Hour | |

| Cargo Capacity | 32.5 cu. ft. | |

| Acceleration (0-60mph) | < 6 seconds | |

| Top Speed | 101 Miles/Hour | |

| Price | $30,700 |

Compared to other popular cars in the U.S., Aptera doesn't differ in size too much from conventional vehicles.

Compared to other common European cars, Aptera doesn't differ in size too much.

FAQ

- How do the windows work?

The top 25% of the door window area is permanently fixed glass and the lower 75% or so retracts into the door as usual.

- How do you get in? There don't appear to be handles

Knock on the panel next to the door or on the back hatch and it swings open! It unlocks using a key card, or you can pair it to your phone.

- Is it safe?

Since the Aptera is classified as an autocycle rather than an automobile, it is not required to conform to the safety standards required of normal cars. However, Aptera has committed to meet or exceed ALL current automotive safety standards and to be safer than most cars on the road!

Despite having only 3 wheels, it is just as stable as most other cars, and even more stable than some! 65% lighter than other EVs, and made of a carbon composite that is seven-times stronger than steel, it has a lower center of gravity than regular cars making it less likely to tip or roll during extreme maneuvers. The egg-shaped driver compartment was inspired by the safety cage of a Formula-1 racecar. Driver and passenger seatbelts and front airbags will be included, and side airbags are being considered. - How much good will the solar panels do?

With the full solar package, they should provide up to 40 miles of charge per day just from being in the sun, whether parked or driving. Optional exterior panels may be able to connect to the system for an additional 1KW of charging (up to 10 miles range per hour) while parked (such as at a campground).

- How much storage space does it have?

There are 32 sq. ft. of storage space behind the seats and another 0.5 sq. ft. storage compartment in back.

- Is this a car or a motorcycle?

Aptera is classified as a motorcycle with correspondingly lower registration and insurance costs. Technically, it is considered to be an autocycle - a fully enclosed vehicle with 3 wheels. While insurance companies still have to determine how much premiums will be, it is likely that insurance will be significantly less than normal cars. No helmet or special license is required.

- How much does it cost?

The Launch Edition configuration (the first 2,000 production run) will have front-wheel drive, a full solar package good for up to 40 miles per day, and a 400 mile range for about $35k. A 250-, 600-, and 1000-mile(!) range option is planned for the future. Although pricing is yet to be finalized, the base model with front-wheel drive, and solar panels on the hood and dashboard good for up to 16 free solar miles per day is currently estimated to be less than $26,000! The top-of-the-line model with 1,000 mile range, 40 miles per day of free solar power, all-wheel drive, and every option should still come in just a little over $50,000!

- Where can I see one to test drive or buy?

The Aptera is currently in the final stages of development, undergoing final assembly validation and safety testing. Go to Aptera's website for more information.

You can place a pre-order now online; A $100 refundable deposit will hold your place in line. Use my referral code (https://lz953.isrefer.com/go/preorder/MxRZYnpx) for a $30 discount on the reservation fee.

Low volume deliveries are expected to be made in late 2025 and ramp up to 20,000 vehicles per year in 2026. There are currently over 50k reservations. - What is it made of?

The Aptera is largely made of extremely high-strength carbon fiber - called CF-SMC, for Carbon Fiber Sheet Molding Compound - which will never rust and is seven-times more resistant to damage than steel, as well as regular SMC (fiberglass) with strategic steel reinforcement for added safety. An aluminum chassis provides the framework for the batteries and suspension.

- How can I get it repaired?

Aptera believes in the right to repair. As such they will be contracting with mobile teams that can affect most repairs. Auto shops that are familiar with the repair of other fiberglass vehicles - such as Ferraris and Corvettes - should be able to make reasonably priced body repairs. If need be, Aptera will send you the parts needed for you to make the repair yourself; It is designed to be repaired with common tools - and video instructions for part replacement and access will be easily available. QR codes printed on many of the components and panels will take you to videos showing you how to disassemble key areas and make repairs or replacements.

Built on First Principles

When we use critical questioning to challenging existing assumptions, we dig right down to the building blocks that those assumptions are based on.

These building blocks are called first principles.

Aptera is taking the electric vehicle industry to task by asking basic questions to help identify the first principles that they will address:

- What are the biggest issues that are faced by electric vehicles and what challenges are there to creating a new vehicle that will address them?

- Range - How much distance will the vehicle go before refueling (charging)

- Charge Time - How much time must be spent in each refueling (charging)

- Charging Locations - Are the charging locations convenient / available

- Cost - Electric vehicles are becoming increasingly expensive

- Difficulty in Manufacturing - There is a significant barrier to entry in bringing a new vehicle to market from scratch

- What are the most basic principles that need to be addressed?

- Range - Options

- Use a bigger battery and/or a make more efficient use of energy

- A bigger battery is more costly, so more efficient use of energy would be preferred

- Where is the most energy used?

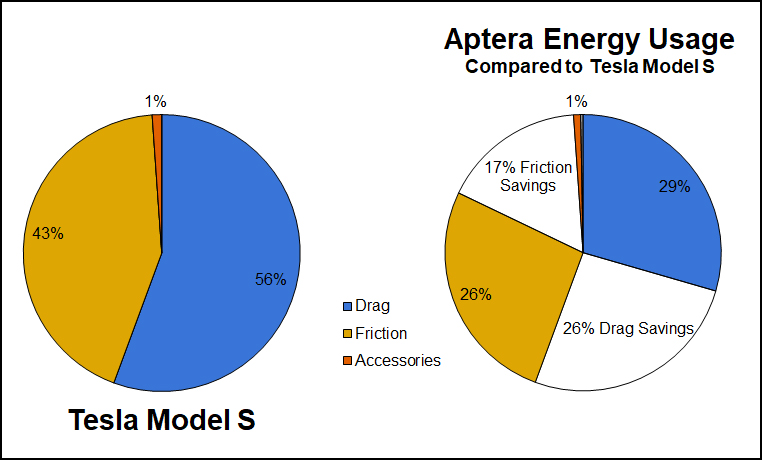

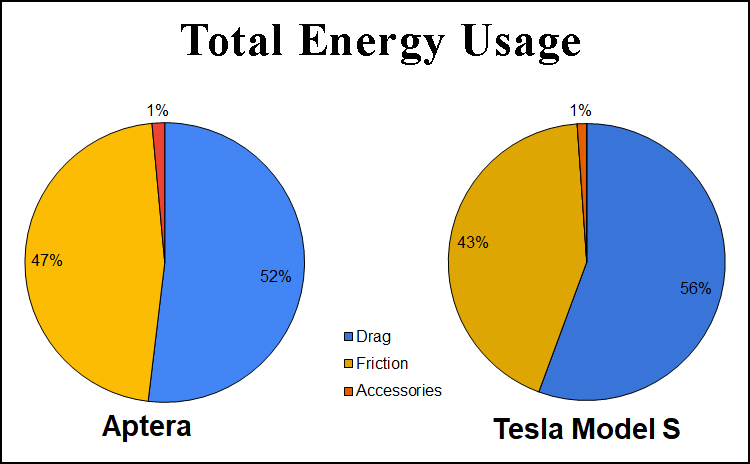

At 65mph, wind resistance uses the most energy. Aptera's unique shape reduces the amount of drag significantly.

The weight of the vehicle also affects the energy required to keep it moving. Aptera's 3-wheel design and 50% reduction in weight further reduces the total energy usage.- Reduce wind resistance (Drag)

- This accounts for 52-56% or more of total vehicle energy use at 65 mph

- Reducing drag cuts total energy usage by 26%

- Rolling resistance

- This accounts for 43-47% of vehicle energy use at 65 mph

- Weight reduction

- Energy usage is reduced by 17% just by reducing the weight by over 50%

- Every 83 pounds of additional weight in the Aptera reduces overall range by around 1%

Even with Aptera's tremendously reduced drag and weight reduction, the total vehicle weight has a significant effect on energy usage.

- Heating / Cooling

- Temperature insulation

- Since Aptera is effectively a rolling Thermos, it takes less energy to heat and cool

Note: With other energy drains reduced, heating and cooling the passenger compartment may draw a greater relative percentage of battery life, so range may be significantly reduced in hotter or colder temperatures. Real-world testing results have not yet been provided.

- Since Aptera is effectively a rolling Thermos, it takes less energy to heat and cool

- Temperature insulation

- Accessories

- Lights

- Front Panel Displays

- Rear-view mirror display

- Side mirror displays

- Infotainment screen

- Data sources

- Navigation information

- Entertainment feeds

- Over-The-Air (OTA) software updates

Details are still pending as to available services and energy needs

- Reduce wind resistance (Drag)

- Reducing weight and using a more efficient design results in only 42% of the total energy required compared to a Tesla Model S to go the same distance.

- Where is the most energy used?

- A bigger battery is more costly, so more efficient use of energy would be preferred

- Use a bigger battery and/or a make more efficient use of energy

- Charge Time - Options

- Use a smaller battery

- Use a faster rate of charging

- Charging Locations - Options

- Provide more locations

Aptera will utilize the Tesla charging network - Practical charging at home

Aptera will be able to be charged using a standard 110v 20A outlet to charge over 100 miles of range overnight.

A 220v 30A (standard dryer) outlet will give you a full charge (over 400 miles) overnight. - Add the ability to charge without a charging station

- Practical solar charging on the vehicle

With 700W of onboard solar panels, Apter may capture up to 40 miles of range parked or driving in the sun.

- Practical solar charging on the vehicle

- Provide more locations

- Cost - Options

- Reduce the cost of materials

- Cheaper battery

- Use lower cost battery materials

- Use a smaller battery

Due to Aptera's thrifty use of power, a much smaller battery can be used for the same or greater range.

- Use cheaper structural materials

- Reduce the amount of material needed

- Create / Use fewer parts Aptera's body is comprised on only six pre-formed parts rather than the 400 or so parts that might otherwise be needed.

- Cheaper battery

- Reduce the cost of labor

- Find cheaper labor

- Require less labor to assemble the vehicle Aptera has many sub-assemblies delivered to the factory. That, in combination with a significant reduction in body parts due to large pre-formed components, allows for faster and easier assembly with a corresponding reduction in labor costs. Many of the parts are pre-formed with assembly 'keys' - much like a Lego - that allow for fast, accurate alignment by hand as opposed to robot or mechanical positioning and forcing parts into place.

- Reduce the cost of materials

- Reduce the difficulty and expense of manufacturing - Options

- Distributed sourcing of components

- Smaller factories

- Fewer part for final assembly

- No paint station

- Fewer / smaller assembly machines

- Reduced labor force

- Reduced cost to establish a factory

- Smaller factory footprint

- Eliminate painting

- Up to 30% of total production cost

- Fewer parts to assemble

- Eliminate painting

- Develop the easiest / fastest assembly process possible

- Smaller factory footprint

- Range - Options

Aptera will be addressing all of these factors through several key first principles:

- Energy Use

- Wind resistance

- Design a vehicle that has the least possible wind resistance

Aptera has a drag coefficient of only 0.13 - the Lucid Air is currently the production vehicle with the lowest coefficient of drag is 50% less efficient with a drag of 0.197.

- Design a vehicle that has the least possible wind resistance

- Light weight

- Smallest possible battery, as it is by far the heaviest component of the vehicle

Aptera's battery is less than 1/2 the size of cars with comparable ranges - Fewest reasonable number of vehicle occupants

Takes advantage of the fact that the average number of occupants in a car is just 1.5 persons, so the initial focus is on a 2-seater model. - Lightest parts as practical

- Make use of the latest materials to reduce weight without compromising strength

- Design each structural component to require the least amount of material without compromising strength and safety

- Smallest possible battery, as it is by far the heaviest component of the vehicle

- Incorporate solar charging to augment and replenish the battery as much as possible

In most climates, solar charging alone can add up to 40 miles of charge.

- Wind resistance

- Cost

- Smallest possible battery, as it is by far the most costly, expensive, and heaviest component of the vehicle

Half the battery size means half the cost without sacrificing range. - Fewest and least expensive parts possible without sacrificing safety

- Fastest and easiest final assembly possible

- Outsource as many components as possible

Aptera only assembles their solar panels on-site. All other components are sub-contracted out and delivered for final assembly. - Structural parts are designed for easy final assembly

Apter's body is comprised of only 15 body parts, including doors and hatches. - Use wraps instead of paint

- Wraps are faster and cheaper than paint

- Wraps do not require the massive factory cost, space, ventilation, and electrical requirements that paint does

- Wraps provide an easier way to change or customize vehicle appearance

- Wraps are energy efficient and have a much lower environmental impact in application

- Outsource as many components as possible

- Smallest possible battery, as it is by far the most costly, expensive, and heaviest component of the vehicle

Construction

Development Progress

- December 4, 2020 The first Alpha prototype - called "Noir" - was shown to the world. The color scheme was all black.

- August 13, 2021 The second Alpha prototype - called "Sol" - was presented. The color scheme was white on the bottom and black on top

- November, 2021 The last of the Alpha prototypes - called "Luna" - was introduced. The color scheme was silver on the lower half and black above

- December, 2021 The Beta version was produced to integrate production pargs and evaluate dynamic and transient vehicle behavior

- September 10, 2022 The Gamma version was announced as a production-intent vehicle used to iron out final production details

- September 2024 The First Delta vehicle was produced with complete Production Intent parts.

As the final step before production and sale, the production process starts with up to 16 Production Intent builds.

These are built using finished, production body parts and components that meet the current design parameters of the finished vehicle.

These 16 preliminary builds will be used for final component fitting and placement, as well as real-world testing of

parameters that, up to now, have only been tested in simulation or in proof-of-concept builds over the last six years.

- PI-1 - This is the first Production Intent vehicle that is built from body parts that come out of the production process. It is not drivable as its purpose is to allow the Electrical Systems Team to finalize cable routing, connectors, and placing of components using actual production parts as the shell.

- PI-2 - October 28, 2024 - This is the first drivable Production Intent vehicles. It incorporate the Body in Carbon (BinC), which is the production body, a full drive train and suspension, and full battery build. This first configuration code named Mercury only has the drive train components installed and serves for the low-speed function test just making sure everything works. Everything on the vehicle is ready for production, there is no tape, temporary wrap, or ties. Everything about the vehicle is designed for high-volume manufacturing - the only exception being the steering wheel instead of a yoke as the low-volume production of the yoke is time consuming and expensive. There is nothing prototype about this vehicle. It currently does not have all of the finished exterior panels or solar. As it is intended as a track vehicle for overall testing and validation, this vehicle will just have minimal interior parts installed. The next test will be the high-speed validation test with all the external surfaces (including the solar panels?), and the production version of the thermal management system. This test will allow the first real-world energy usage and range measurements, plus it will evaluate the core efficiency figures.

- PI-3 - The next iteration for further validation and testing code named Gemini, particularly in terms of the full electrical system, which will likely include the solar panels and provide some real-world charging information.

- PI-4 - January 7, 2025 - This is scheduled to be the first complete vehicle - inside and out code named Apollo. It will be used to further test fit and finish, further integration and testing of interior components, panels, and materials. It will be the first vehicle to look in all ways like the vehicle that is intended for eventual sale. It will be on display for the first time at the Consumer Electronics Show (CES) in Las Vegas from January 7-10, 2025.

- PI-5-16 - These vehicles will be used for performance and safety testing in the real world, and as media demonstrators of the completed vehicle. Fully functional in all ways, the integration and testing of all components will allow the development team to discover any weaknesses and continue the refinement of the vehicle as a whole. Replacement parts may swap out some of the initial components as refinements and improvements continue to be made.

- December 2024 First VIN Seen: 5WTA22208NC000007

Aptera's design process is one of the most innovative and effective ones in the industry. Using computer simulations, the shape of the vehicle

has been finely calculated to minimize drag. Compared to other vehicles, the Aptera has less than two-thirds the drag of the most efficient Tesla.

Each part has been computer modeled and analyzed for strength and excess material has been eliminated, helping to reduce the overall vehicle weight.

The entire vehicle has been put through extensive simulations to optimize and fine-tune the handling. Real-world measurements conducted on the

resulting vehicles found a 95% correlation to the simulations, giving them increased confidence in their methodology.

Aptera's passenger compartment is built along the lines of a Formula-1 racecar with a protective shell that is unsurpassed in the automotive industry.

Every component of the Aptera has been simulated in a computer and designed to fit together perfectly. This will help make Aptera the easiest car to

assemble ever.

When the actual parts were manufactured, there were no surprises. Every part had be thoroughly designed and refined in a computer. Every part was

assembled in a 3-D simulation before the parts were molded, cast, or built, so everything fit together in real-life exactly as it did in the

computer simulation. The fit and finish of the result is nearly perfect.

By utilizing fully-tested, off-the-shelf parts and custom and semi-custom sub-assemblies, the manufacturing process is widely distributed and

a relatively small factory can be used to quickly and easily assemble all of these component parts into the final vehicle. In fact, Aptera estimates

that a warehouse of only 100,000 sq. ft. and no special facilities can be converted into another Aptera assembly plant.

As each molded component has been designed with efficiency in mind, channels and connections for wiring and other components are already fully incorporated

in each molded piece. This cuts down on the various assemblies, and myriad brackets needed to run wiring, mount components, and incorporate each part

into the final assembly.

Aptera took a page from Tesla's playbook and is casting the body in just a few parts. The main body of the Aptera, rather than consisting of hundreds of

parts, is comprise of just six main molded components and a total of around 15 parts makes up the entire body structure, including hatches and doors.

Each of the parts is designed with 'keys' - built-in alignment guides so that the parts go together like Lego pieces; the alignment is easy and perfect every time!

The molded parts all come out perfect. There is no warpage or variation like you find in metal parts. Once molded, the parts are completely rigid

and will never degrade or warp.

Aptera is designed with cradle-to-grave planning. Many components are derived from recycled or renewable materials, and are designed to themselves be

recycled at the end of their lifespan.

The molded parts use dies that are computer designed to have minimal waste, and the waste material that they do have can immediately be recycled

into the next piece.

Rather than painting their vehicle, Aptera has chosen to use vinyl wraps. This not only eliminates one of the costliest, most massive production stations,

but it also greatly reduces the energy requirements and environmental impact of painting. The wrap is free of volatile organic compounds (VOCs) which are released

into the air by paint and cause health issues and contribute to ozone depletion.

CPC Group produces the BinC (Body in Carbon) - the six main pieces that go into the full body of the Aptera. They use Carbon Fiber Sheet Molding Composite (CFSMC) to mold each part. They use large steel blocks that are computer carved to create molds for each piece. The CFSMC material is put into this mold after being roughly laid out in the shape of each piece. These steel molds are heated to about 150 degrees C and pushed together with thousands of tons of pressure. The molds have been built so that the exact volume needed for each piece has been exactly calculated so that there is very little excess. Once the molds are heated initially, they can be used to stamp out parts at the rate of one part every 6-12 minutes, with minimal heat needing to be added for each piece to keep the molds at the necessary temperature. This results in a very energy efficient production process for each piece. By using carbon fiber body parts, the entire body weighs less than 200 pounds. It also allows assembly by hand. Robotics or lifting machinery is not required as the parts can be lifted and positioned by one or two people. Instead of welding, the parts are chemically bonded to each other, resulting in a join that is as strong or stronger than the parts themselves.

- Strength

- Cost

- Life Cycle Recycling

- Raw Materials

- Processing

- Manufacturing

- Distributing

- Product Use

- Disposal

Most of the Aptera is constructed of either CFSMC or aluminum, with some steel. Other areas are bamboo-based or other sustainably produced materials.

The waste from CFSMC molding is very small. The trimmings can immediately be ground up and recycled in the next batch.

Transporting products usually involves burning fossil fuels. The lighter the item, the less it pollutes in reaching its destination.

Due to its high strength-to-weight ratio, CFSMC may reduce weight by up to 70% over other materials.

CFSMC is easily recycled. Old material is simply ground up and used again.

Aluminium is also easily melted down for recycling.

Carbon Fiber Sheet Molding Composites (CFSMC) are up to 10 times stronger than steel by weight.

Although CFSMC is more expensive and complex to manufacture than steel, it returns significant savings in the ability to construct large components that would normally require many parts to assemble using metal. It is not subject to corrosion or fatigue and so has a longer lifespan.

Aptera - The Company

Mission Statement

Working to make every journey powered by the sun!

Stock Symbol: SUNA (NASDAQ - Pre-IPO)

History

In 2006, Accelerated Composites was founded by Steve Fambro. Soon after, Chris Anthony joined and they changed the name to Aptera announcing a three-wheeled motorcycle design that would get 330 mpg using a combination of 12 HP diesel engine and 24HP motor with a selling price under $20,000.

In 2008, after raising $24M, Aptera ousted Steve and Chris, and accepted 4,000 $500 deposits for the vehicle, which was supposed to be delivered that year.

In March, 2009, the U.S. government denied loans under the Advanced Technology Vehicles Manufacturing Loan Program, due to the loans being limited to 4-wheel vehicles. That same year, Aptera's prototype had a cameo appearance in Star Trek: The Motion Picture.

In 2011, Aptera started returning deposits to its customers and the company liquidated, selling off its assets and IP to Chinese automakers, who failed to successfully develop the idea.

In 2019, Steve and Chris resurrected Aptera. Electric vehicles were no longer just concept cars; Tesla was having a record year and the battery, motor, solar panel technologies as well as charging networks had significantly advanced to the point that Aptera believed they could practically create a vehicle that derived significant power from incorporated solar panels.

Aptera raised $200k in 2019 in a WeFunder campaign, and double that in 2020.

In early 2021, Aptera closed a $4M Series A funding round and started taking $100 deposits for a future vehicle. They built three engineering prototypes, and raised over $39M in funding.

By the end of 2022, they reported $39.9M in total assets and over 18,000 reservations<\p>

In 2023, after missing several hopeful production targets, Aptera opened another crowdsourcing program, called the Accelerator Program. Starting the, investors who purchased (another) $10k of Aptera stock would receive one of the first 2,000 Aptera Launch Edition vehicles to be produced. The delivery slots would go according to the highest overall investors.

In 2024, after raising over $35M in the program, the Accelerator program completed and was closed.

On May 16, 2024, Aptera announced an agreement with US Capital to fund their production plan and start selling their cars to the public in early 2025.

At this time, it appears that Aptera early investments qualified for the IRS 1202 Qualified Small Business Stock Gain Exclusion

This is a federal capital gains exclusion (check your state code to see if your state conforms to the same guidelines. California does not).

To qualify, the business must meet the following criteria:

- The business must be a C corporation

- It must be engaged in a qualifying business

- It must used at least 80% of its assets to actively conduct business

- Less than 50% of its total assets may be working capital

- The company may have no more than $50M tax basis in assets prior to stock issuance

Aptera, to the best of my knowledge, easily meets all of these requirements.

Therefore, if you invest in Aptera today, and hold your investment for at least five years, your profit on Aptera stock will be excluded from federal capital gains (currently at 23.8%) for the greater amount of 5 times your initial investment, or $10M of gains.

Further Information

The cash compensation for the officers and directors of Aptera, for 2023 were:

- Chris Anthony (CEO / Director) - $262k in 2022, $212k in 2021

- Steve Fambro (CEO / Director) - $257k in 2022, $181k in 2021

- Brian Snow (Director) - $135k for 2022

- Sarah Hardwick (CMO) - $231k for 2022

More information will be made available soon

My Experience

- I first heard about Aptera sometime in the mid-2000's when they were trying to produce a diesel powered vehicle that could get 300 mpg. I was intrigued by the concept, but was never an investor, as at time I believed it to be pretty much a concept car rather than a serious contender. The company effectively folded in 2011.

- I first heard about the resurrection of Aptera in the spring of 2020. They were doing a Wefunder crowdfunder to raise at least $550k. They were offering a free reservation (worth $100) for a minimum investment of $1,000. After reading through all of their history and goals I immediately signed up, figuring if they went under, a $1,000 investment in a future I believed in was certainly worthwhile.

- I put in my (free) reservation right away for a 600k range vehicle with full solar, all-wheel drive, and more.

- In September, 2021, I increased my investment to exceed $10k, which further entitled me to a 5% discount if/when they ever produced their vehicle

- In December, 2023, they were having an Accelerator Program: For new investors of at least $10k, they offered a pre-order list to receive one of the first 2,000 Apteras to be produced, in a configuration that they called the Launch Edition. It was nearly the same as my initial configuration, except that they would be producing the 400-mile range version as their introductory vehicle. I made a further investment and garnered spot #712 to receive the Launch Edition, which will include a specially numbered vehicle and serialized limited-edition hardback book about producing the first Apterae, featuring CAD and design images from the development.

- In January, 2024, Aptera announced the completion of their Accelerator Program, and in June, 2024 they announced that they had successfully raised over $35M with 991 new investors and 2,072 slots filled.

- As of May, 2024, they have received the first of 16 progressive Production Intent builds, which will be used for final development of the manufacturing process, suspension refinement and, ultimately, virtually complete vehicles to show to the public and perform crash and safety testing on.

- They current expect to be producing vehicles for further internal assessment by the end of the year, and start production in early 2025.

- On May 16, 2024, they announced that US Capital would be providing funding for their production plan to get vehicles into production by 2025. The program is only open to accredited investors who can invest at least $50,000.

- On September, 2024, I received notice that my position on the Accelerator Board (and thus my delivery vehicle number) is 807, which they were projecting would be delivered in H1, 2025

- On December 2, 2024, Aptera re-opened its crowdfunding program with a minimum investment of $1,000 and a share price of $14.80